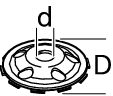

Mounting/changing the diamond cup wheel (see figure B)

All diamond cup wheels mentioned in these operating instructions can be used.

Pay attention to the dimensions of the diamond cup wheel. The diameter of the hole must match that of the mounting flange. The mounting hole of the diamond cup wheel may not be enlarged. Do not use an adapter or reducer.

The permissible speed [min -1] or the circumferential speed [m/s] of the diamond cup wheels used must at least match the values given in the following table.

Therefore, observe the permissible rotational/circumferential speed on the label of the diamond cup wheel.

max. [mm] | [mm] |

|

| |

|---|---|---|---|---|

D | d | [min–1] | [m/s] | |

| 125 | 22.2 | 8500 | 80 |

Choose a diamond cup wheel suitable for the material to be worked. Please also observe the material information on the packaging of the diamond cup wheel.

Clean the grinding spindle (12) and all parts to be mounted.

Place the mounting flange (13) on the grinding spindle (12) so that the centring collar is on the outside. The mounting flange (13) must engage on the flats of the grinding spindle (12) (anti-twist protection).

A plastic part (O-ring) is fitted around the centring collar in the mounting flange (13). If the O-ring is missing or damaged, the mounting flange (13) must be replaced before operation can resume.

Place the diamond cup wheel (14) on the mounting flange (13).

Press the spindle lock button (9) to lock the grinding spindle.

Screw on the clamping nut (15) and tighten it with the two-pin spanner (16).

Ensure that the collar of the clamping nut (15) faces outwards, as shown in the figure.

- After mounting the diamond cup wheel and before switching on, check that the diamond cup wheel is correctly mounted and that it can turn freely. Make sure that the diamond cup wheel does not graze against the protective guard and extraction hood or other parts.

When transporting the power tool, the diamond cup wheel (14) should be removed to avoid damage to it.

- Do not touch the diamond cup wheel until it has cooled down. Diamond cup wheels become very hot whilst working.

Press the spindle lock button (9) to lock the grinding spindle.

- Do not press the spindle lock button while the grinding spindle is moving. The power tool may become damaged if you do this.

Loosen the clamping nut (15) with the two-pin spanner (16) and unscrew the clamping nut (15). Remove the diamond cup wheel (14).